eVTOL Testing

Summary

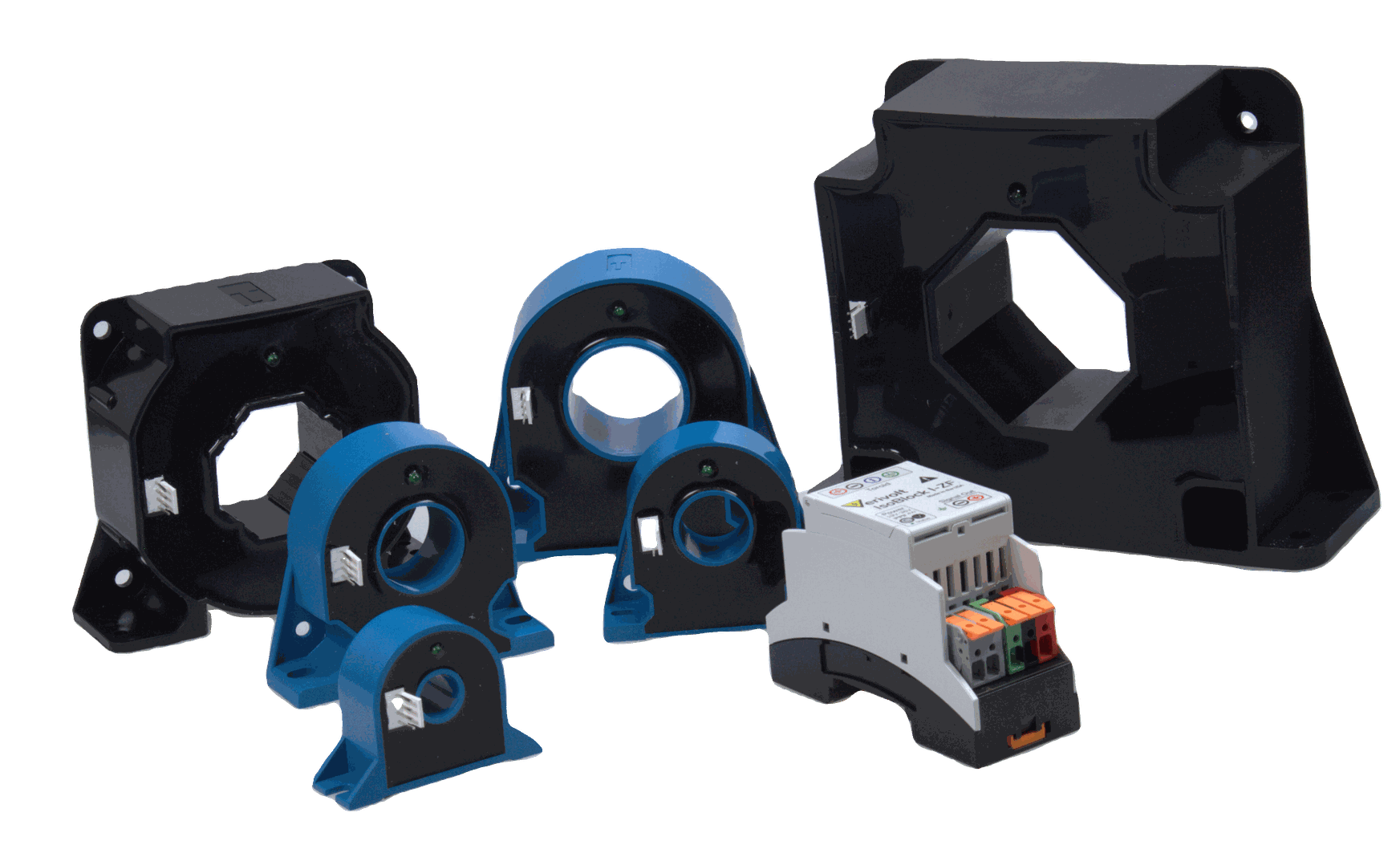

Discover Verivolt's high-performance voltage and current sensors for eVTOL aircraft testing and validation. From power distribution, propulsion to battery performance testing, our wide range of solutions ensures the accuracy and reliability essential for electric vertical take-off and landing systems.

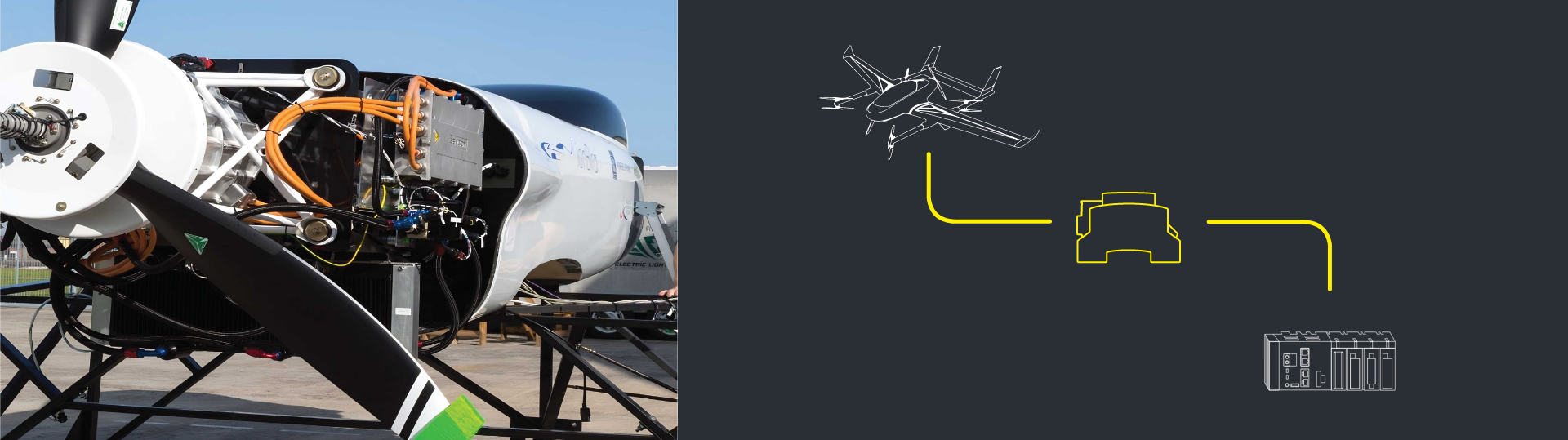

Product in Use

Ensuring accuracy & reliability for eVTOL aircraft testing & validation

Verivolt offers high-performance sensors designed to meet the stringent demands of the eVTOL industry. With high isolation, broad bandwidth, and excellent common-mode rejection, our solutions enable testing across propulsion, battery management, and power electronics systems. Thanks to our deep understanding of test and measurement requirements and industry standards, Verivolt ensures the accuracy and reliability essential for electric vertical take-off and landing (eVTOL) aircraft testing and validation.

Challenges in Validating and Testing eVTOL Applications

eVTOL aircraft, combining electric propulsion with vertical take-off and landing capabilities, are poised to transform urban mobility by reducing traffic congestion and emissions. Testing and validating the electrical and propulsion systems in eVTOLs involves a range of technical and operational challenges due to the high complexity, safety-critical nature, and novel architectures of these aircraft.

Key challenges include high voltage and current testing, as these systems often operate at several hundred volts (sometimes exceeding 800V) and high current levels, particularly in propulsion and battery systems.

This complexity is further compounded by the use of multi-rotor or distributed electric propulsion systems with intricate control and synchronization requirements—powered by batteries that must undergo extensive charge/discharge testing under a variety of environmental and load conditions.

Additionally, as the eVTOL industry is still an emerging field, it suffers from a lack of standardized protocols. Many testing standards are still under development, making cross-comparison and certification more difficult. Engineers are often required to design custom test setups and navigate evolving regulatory frameworks such as those from the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA).

How Verivolt sensors help solving these Challenges

Verivolt sensors, such as the IsoBand V, IsoBlock I-ZF, and IsoBlock V, are designed to address the specific challenges associated with eVTOL aircraft testing and validation.

These tests include:

- Power Distribution and Bus Testing

- Electrical Propulsion testing

- Thermal Management System Validation

- Battery Performance Testing

- Avionics and Control System Power Testing

- System Integration and Endurance Testing

- Fault Injection and Safety Testing

- Efficiency and Loss Analysis

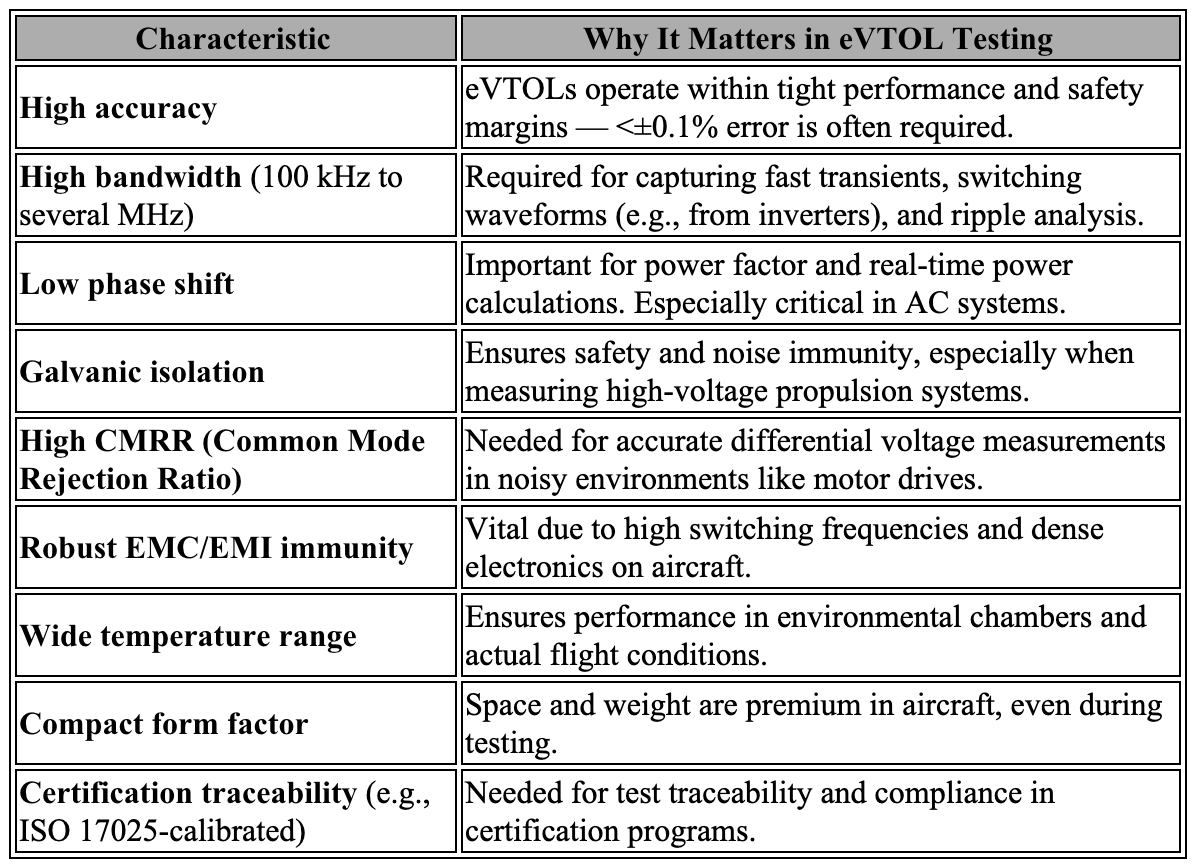

How our sensors add unparalleled performance to test setups

Verivolt sensors are used in the above application fields because they present the following characteristics:

With these capabilities, our sensors are an important complement to traditional DAQ (Data Acquisition) systems, expanding their measurement range, preserving accuracy, and adding unparalleled isolation levels to test setups.

Conclusion

Verivolt sensors feature specifications that are increasingly needed for the validation and testing of eVTOL aircraft and systems, helping professionals meet stringent requirements and supporting innovation in the field of sustainable aviation.